Services

VIKAT Engineering recognise that our employees are our most important resource. Our Engineers, Technicians and Support Personnel have the expertise needed to address a broad spectrum of engineering services we offer. The Company is also associated with experienced professionals working abroad to assist its engineering team in specialised areas. We undertake consultancy assignments in various disciplines of engineering.

Advanced technologies including INVENTOR and AutoCAD are used for design works.

- Feasibility Study : We do feasibility study for a new material handling system as per Client requirement. We also cross check the possibility of capacity augmentation for an existing system.

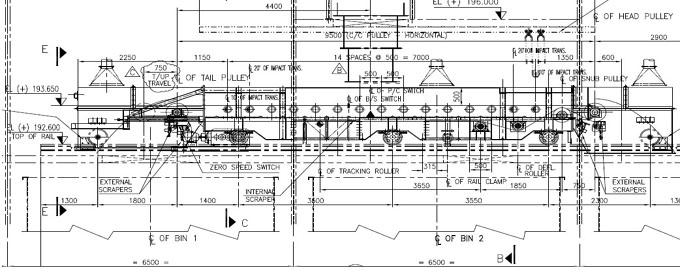

- Brown Field Material Handling : If a new bulk material handling system is required inside a plant full of similar or other types of existing system, our expertise lies in precise and optimised design and detailing from layout/routing to manufacturing/fabrication drawing.

- Capacity Augmentation : This can be done on an existing system up to a certain limit without making major changes.

- Green Field Material Handling : If a new bulk material handling system is required on a green field plant, our expertise lies in precise and optimised design and detailing from layout/routing to manufacturing/fabrication drawing. Preparation of calculation for belt conveyor capacity, power required, tensions, pulley shaft etc. Selection of belt, motor, gear box, couplings, idler etc. Preparation of mechanical GA of belt conveyor, chute drawing, take-up drawing, drawing of technological structures etc.

- Wagon Loading System : Wagon loading can be done with the help of no. of conveyors, storage bin, weigh feeder along with programmable logic circuit situated in side a building.

- Mica Cleaning & Bagging : With the help of screw conveyor and a rotary magnetic cleaner the mica becomes yarn & magnetic particle free. The clean mica is collected in no. of bags on a weighing turn table and packed for despatch.

- Equipment Handling : Without or minimum approach to any essential equipment, maintenance/replacement can not be done easily. With the help of our unconventional robot type equipment which can be prepared as per site condition, the maintenance/replacement can be done.

- Equipment Design : We prepare the design, drawing, estimating, costing for all conventional & non conventional equipment related to material handling. Design & detail for mechanical equipment like roller conveyor, chain conveyor, pusher, charging machine, etc. Preparation of P&I, layout, GA and detail for heat treatment furnace like rotary hearth furnace, walking hearth furnace, walking beam furnace, bogie hearth furnace, pusher type furnace etc. Design & Detail of Mica Cleaning & Bagging System, Car Ramp, Coil Lifter, Wagon Lifter etc.